Satinal: STRATO® RIGIDO structural component for multiple combinations

STRATO® RIGIDO is a special structural interlayer that ensures one of the highest levels of protection against strong impacts. Even if the glass component breaks, the laminated structure is not weakened, so the stability and safety of the product are preserved.

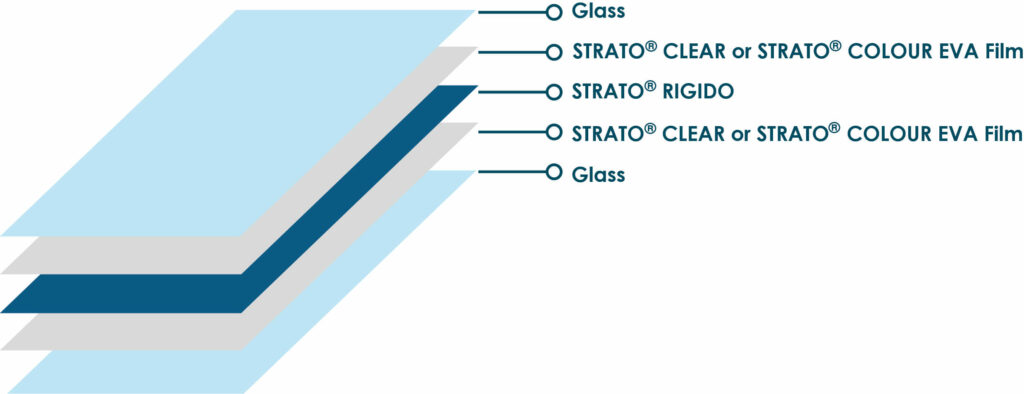

STRATO® RIGIDO must be laminated with two sheets of STRATO® EVA film, so the mechanical, adhesive and optical properties can be achieved.

STRATO® EVA, that ensures the adhesion of STRATO® RIGIDO to glasses, is a thermosetting material. Differently from PVB film, it creates three-dimensional bonds at molecular level during the lamination process, making STRATO® EVA laminated structurally safe.

The great mechanical properties of STRATO® EVA combined with the stiffness of STRATO® RIGIDO allow to laminate any thickness of glass, guaranteeing the same structural loading any time and over time.

Open edges applications

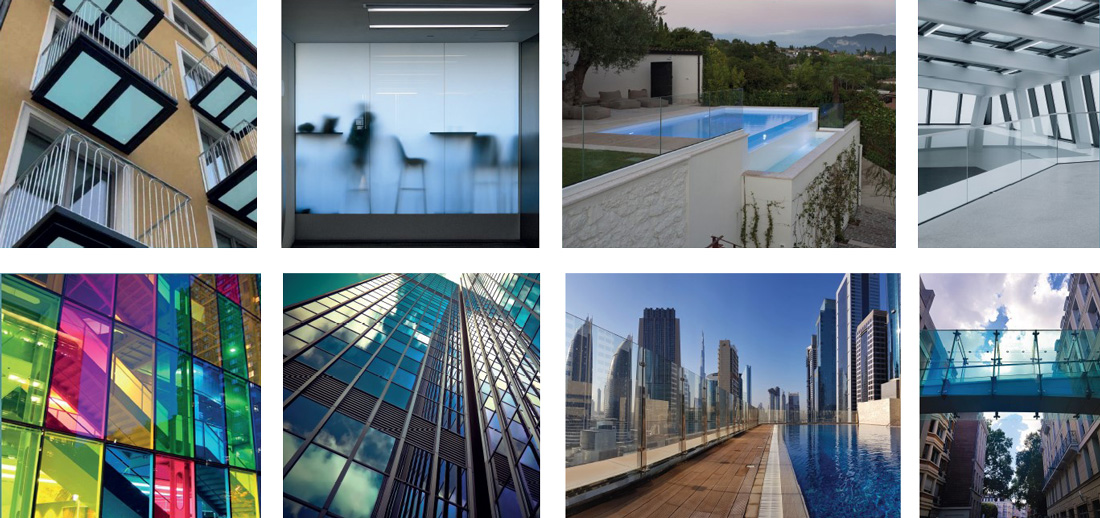

STRATO® RIGIDO is not a hygroscopic material and therefore does not fear moisture. Moreover, STRATO® EVA film is not sensitive to humidity, water, temperature fluctuations and more: that is why STRATO® product range is compatible with indoor as well as outdoor applications without the risk of delamination. So, no worry to install STRATO® EVA laminated glasses at the most extreme weathers.

Transparency and frosting effect

When transparency comes as a dictat, it is recommended to laminate STRATO® RIGIDO with two sheets of STRATO® CLEAR EVA film, known as the non-plus-ultra of EVA films for the architectural glass market. It provides a completely natural, transparent and neutral-looking glass thanks to its high degree of transparency and UV protection.

If privacy is a must, STRATO® RIGIDO can be combined with STRATO® FROST EVA film product range, consisting of three different finishings (STRATO® LEGGERO, STRATO® SATINATO and STRATO® LATTE). It allows to achieve different levels of opaque effects and transparencies (from 2% up to 65% of light transmission) according to STRATO® FROST EVA film finishing chosed. It also plays a double action, capturing and spreading the light homogeneously and without reflections.

Integrate Colours

STRATO® RIGIDO can be assembled with STRATO® Colour EVA film, matching colourful and safety all in one project.

STRATO® COLOUR EVA film collection offers both solid and transparent colours, allowing the personalization of structural surfaces with modern and cutting-edge shades.

It is also possible to combine STRATO® COLOUR EVA film with STRATO® RIGIDO and STRATO® FROST EVA film, all together in one laminated glass, for a perfect colour-frosted finishing.

Multilayer combinations: what does it mean?

Safety and stiffness are mandatory when it comes to project buildings, canopes, ceilings, floors, facades and more. It is clear that the combination of safety and styling is definitely possible with STRATO® product range.

STRATO® RIGIDO must be assembled inside two sheets of STRATO® EVA and two panes of glasses, but multiple combinations are still possible.

Here below are two infographic examples that easily explain how panes of glass can be combined with multiple sheets of STRATO® RIGIDO and STRATO® EVA films, meeting the approval of architectural guidelines in terms of structural safety.

Dimensions, thickness and length

Last but not least, dimensions are important. That is why STRATO® RIGIDO is available in different formats and widths. Moreover, STRATO® RIGIDO is available in different thicknesses and roll lengths.

Satinal Spa has been the first EVA film production site in Italy, a reference point in Europe for the supply of 100% made in Italy interlayers. To this, it is added STRATO® RIGIDO, available in different sizes and thicknesses, to respond to multiple purposes of use.

The application of STRATO® EVA film is a process requiring great precision for the applied temperatures and cycle times. The quality controls, which are carried out in Satinal’s R&D Lab, aim to guarantee perfect adhesion of the material to the glass surface. The deep experience acquired by Satinal in the treatment of EVA-based materials is essential to master its potential applications and fully exploit their characteristics.