Does STRATO® provide performance with respect to solar control and energy saving?

Satinal has developed STRATO® FRESCO, a new generation of high-performance EVA film using nanoparticle technology.

FRESCO is designed to give laminated glass more efficient solar heat control properties than monolithic transparent glass and laminates with traditional transparent EVA film: the film absorbs UV rays and infrared energy (NIR), allowing maximum visible light transmission.

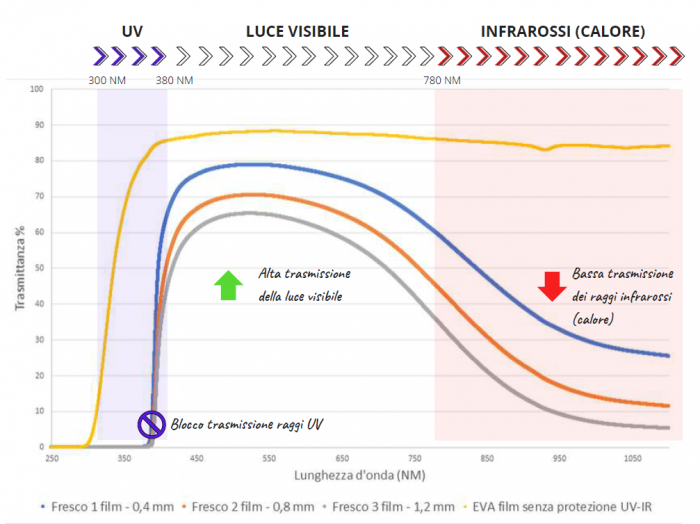

The graphic clearly shows this concept: a laminated glass with EVA film without protection UV-IR (yellow line), has a high transmission of visible light but allows to pass both UV rays, very harmful to people and objects, and Infrared rays.

However, if we analyze the behavior of a laminated glass with one (blue line), two (line orange), or three films (grey line) of STRATO® FRESCO, you will notice that the value of the transmission of the visible light (max 80%), is opposite to that of the infrared rays (min. 5%).

These characteristics are very important because they let you recreate in buildings, houses and apartments, a comfortable indoor environment, especially during the summer season.

By reducing the use of air conditioning, you will get economic benefits: reduction of electricity costs and reduction of greenhouse gas emissions-.

STRATO® FRESCO can replace low-emission glass (Low-E) because it reduces heat transmission with the advantage of not having a delicate glass to handle: it represents a cheaper solution from a processing, handling and purchasing point of view.

What are the advantages?

- Constantly high light transmission with tunable solar heat gain coefficient as low as 0.3

- Color neutralit

- Low haze

- Low reflection of visible light

- Significant and sustainable energy savings

- Compatible with STRATO® Extra Chiaro System

- Lowering your energy cost and CO2 footprint of your building and car, block solar heat radiation

- It can be easily tuned by customer to any desired solar heat performance

Where can it be applied?

- Suited for curved glass

- Shelters

- Curtain walls

- Storefronts

- Sloped/overhead glazing

- Residential and commercial facades